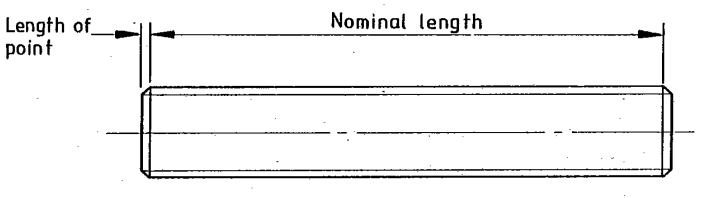

(a) studbolt threaded full length

General

The forms of the studbolts shall comply with those shown in figure 4(a), (b),

(c) or (d). Dimensions shall be as given in 3.1.2 to 3.1.8 and tables 16 to 19.

The tolerances on nominal length shall be as given in table 17.

NOTE 1. The preferred nominal lengths are given in table 18.

If lengths other than these are requested (see appendix C) the increments of

nominal length should be as follows:

(a) 14 in for lengths up to and including 12 in;

(b) ½ in for lengths over 12 in.

NOTE 2. The length of point is excluded from the nominal length (see 1.2.2.1).

For studbolts having plain portions as shown in figures 4(b), (c) and (d), the basic length of thread shall

be equal to the nominal diameter plus 0.375 in.

For studbolts in figures 4(b) and 4(c) , the limits on the length of thread shall be plus 2 pitches, minus

0.

The basic length of the reduced diameter portion shall

be equal to 0.6 times the nominal diameter (see figure

4(d) and item (d) (5) of appendix C).

The following tolerences shall apply to this dimension:

(a) +0.030,-0 in for lengths up to and including 1.2 in;

(b) +0.060,-0 in for lengths over 1.2 in and up to and including 2.1 in.

The following tolerances shall apply to this dimension:

(a) ±0.030 in for lengths up to and including 2 in;

(b) ±0.060 in for lengths over 2 in and up to and including 6 in.

The ends of studbolts shall be finished with a point having an included angle of approximately 90° to a depth slightly exceeding the depth of thread. Nominal lengths of points for reference purposes shall be as given in table 19.

The diameter of the plain portion shall not exceed the maximum values given in table 16.

NOTE. The diameter of the reduced portion should be stated by the purchaser in the order (see appendix C). Under

normal conditions a minimum of 0.95 times the minor thread diameter is used, but for studs subject to

particularly onerous conditions (such as high temperature service) diameters less than this may be used.

| Diameter of plain portion,maximum and minimum sizes of studbolts: Inch series | ||||

|---|---|---|---|---|

| Nominal diameter | Nominal diameter design | Reduced diameter design 1) | ||

| max. | min. | max. | min. | |

| in | in | in | in | in |

| 1/2 | 0.500 | 0.496 | 0.373 | 0.364 |

| 5/8 | 0.625 | 0.619 | 0.474 | 0.464 |

| 3/4 | 0.750 | 0.744 | 0.581 | 0.571 |

| 7/8 | 0.875 | 0.867 | 0.685 | 0.675 |

| 1 | 1.000 | 0.992 | 0.786 | 0.774 |

| 1 1/8 | 1.125 | 1.117 | 0.905 | 0.893 |

| 1 1/4 | 1.250 | 1.242 | 1.022 | 1.010 |

| 1 3/8 | 1.375 | 1.365 | 1.142 | 1.126 |

| 1 1/2 | 1.500 | 1.490 | 1.260 | 1.244 |

| 1 5/8 | 1.625 | 1.615 | 1.381 | 1.365 |

| 1 3/4 | 1.750 | 1.740 | 1.498 | 1.482 |

| 1 7/8 | 1.875 | 1.865 | 1.620 | 1.604 |

| 2 | 2.000 | 1.990 | 1.732 | 1.716 |

| 2 1/4 | 2.250 | 2.240 | 1.968 | 1.952 |

| 2 1/2 | 2.500 | 2.490 | 2.210 | 2.192 |

| 2 3/4 | 2.750 | 2.740 | 2.440 | 2.422 |

| 3 | 3.000 | 2.990 | 2.685 | 2.667 |

| 3 1/2 | 3.500 | 3.485 | 3.160 | 3.138 |

| 3 3/4 | 3.750 | 3.735 | 3.397 | 3.375 |

| 4 | 4.000 | 3.985 | 3.635 | 3.613 |

| 1) Based on tolerance class h 13 of BS 1916. | ||||

Screw threads shall be ISO Unified inch coarse pitch series (UNC) for sizes up to and including 1 in diameter,

and 8 threads/in (8 UN series) for sizes 1/4 in and above in accordance with BS 1580.

NOTE. The tolerance class should be stated by the purchaser in the order (see appendix C), but for most

conditions the following are applicable:

(a) class 2A (see BS 1580) for grades B7, L7, B7A and B16, B16A, B16B;

(b) class 2AG for other materials.

| Tolerances on nominal length of studbolts: inch series | ||

|---|---|---|

| Nominal diameter | Length | Tolerances on length |

| in | in | in |

| ≤ 1 | ≤ 6 | ± 0.030 |

| > 6 | ± 0.045 | |

| > 1 ≤ 2 | ≤ 7 | ± 0.045 |

| > 7 | ± 0.060 | |

| > 2 ≤ 4 | All | ± 0.075 |

| Preferred nominal lengths of studbolts: inch series (based on flanges as specified in BS 1560: Section 3.1) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Preferred nominal lengths | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 2 1/4 | 2 1/2 | 2 3/4 | 3 | 3 1/4 | 3 1/2 | 3 3/4 | 4 | 4 1/4 | 4 1/2 | 4 3/4 | 5 | 5 1/4 | 5 1/2 | 5 3/4 | 6 | 6 1/4 | 6 1/2 | 6 3/4 | 7 | 7 1/4 | 7 1/2 | 7 3/4 | 8 | 8 1/4 | 8 1/2 | 8 3/4 | 9 | 9 1/4 | 9 1/2 | 9 3/4 | 10 | 10 1/4 | 10 1/2 | 10 3/4 | 11 | 11 1/4 | 11 1/2 | 11 3/4 | 12 | 12 1/4 | 12 1/2 | 13 1/2 | 14 | 14 1/2 | 15 | 15 1/2 | 16 | 16 1/2 | 17 | 17 1/2 | 18 | 18 1/2 | 19 | 19 1/2 | 20 | 20 1/2 | 21 | 21 1/2 | 22 | 22 1/2 | 23 1/2 | 24 | 24 1/2 | 25 | 25 1/2 | |||

| 1/2 | x | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8 | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | |||||||||||||||||||||||||||||||||||||||||||

| 7/8 | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8 | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | |||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4 | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | |||||||||||||||||||||||||||||||||||||||||||

| 1 3/8 | x | x | x | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | x | x | x | x | x | x | x | x | x | x | x | x | x | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/8 | x | x | x | x | x | x | x | x | x | x | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4 | x | x | x | x | x | x | x | x | x | x | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8 | x | x | x | x | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | x | x | x | x | x | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4 | x | x | x | x | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2 | x | x | x | x | x | x | x | x | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4 | x | x | x | x | x | x | x | x | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | x | x | x | x | x | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2 | x | x | x | x | x | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4 * | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4* | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

*Preferred nomial length to be completed in a letter revision of this standard Choke of length. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Table 19. Length of point (see 3.2.6) for studbolts: inch series | |

|---|---|

| Nominal diameter | Length |

| in | in |

| 1/2 | 0.057 |

| 5/8 | 0.066 |

| 3/4 | 0.071 |

| 7/8 | 0.078 |

| 1 and greater | 0.087 |